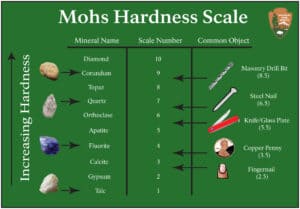

If you are in the jewelry business then you know how important this scale is. we use this tool to identify hardness of minerals.

First a little history:

Carl Friedrich Christian Mohs was a German geologist AND mineralogist. In 1822 he created the Mohs scale. He determined that you could tell which minerals were harder based upon the scratch test. Using several harder materials to perform the tests he was able to rank minerals according to their hardness. As a result this 200 year old scale is used industry wide today.

Not only are minerals numbered one to ten, but also they are not evenly spaced. For example quartz, which is a SEVEN is actually 100 times harder than talc. A diamond which is a TEN is actually 1500 times harder than talc.

Keep in mind that these 10 minerals were chosen for the scale. As new minerals are mined and discovered they use this scale to determine the hardness.

What scratch tools are used?

We use a fingernail for the basic scratch. If it leaves a mark on the mineral then this mineral (talc) is considered a ONE on the scale. Moving up the scale we use a copper penny, a knife, steel nail and a drill bit. In the case of quartz (which we use widely in jewelry design) it can only be scratched with a steel nail. This makes quartz a SEVEN on the hardness scale. SEVEN is a durable hardness and can be used in rings or cuffs as well as earrings and pendants. The hardest mineral (number TEN on the scale) is diamond! Even a drill bit has trouble scratching the surface. Look at the chart above to get the full details.

Follow me on my design journey and become a collector. Not only do my collectors receive first look at my newest designs but the also have the advantage of Collector-only discounts and specials. It’s Free. And you Get 15% off your first order.

Here’s How

Shop Here for all my Designs

Leave a Reply